A prototype It's like a mockup that can be used to perform tests and designs of what will later be a final product. The use of 3D printers It has facilitated the widespread obtaining of prototypes by reducing production costs and especially opening up many possibilities in obtaining useful and functional products for all. These types of activities, which will not stop developing and that will be jobs of the future, require high specialization.

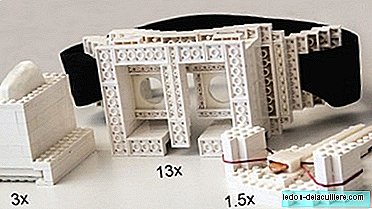

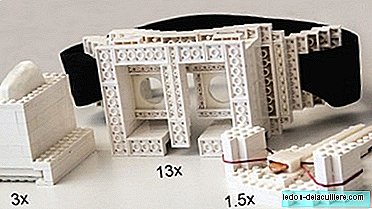

The challenge of faBrickation is to get rapid prototypes using 3D printers although the main novelty is that they use Lego pieces to get results quickly saving a lot of time. In the image you can see the time savings using this proposal from faBrickation. Once it is verified that the design meets the expectations, it is time to make the final product.

In the video of Stefanie Mueller, project leader faBrickation at Human-Computer Interaction group of the Hasso Plattner Institute in Germany you can see examples of design and practice using Lego pieces. And it is that with this type of prototypes you can solve the pressures of time and results that customers request when they demand new products, new functions or accelerate development times.

Another key of faBrickator is that once the work has been done with the Lego they have managed to simplify the use of the 3D printer by printing in parts and turning the typical brick designs into smoothed shapes and according to the final design Of the piece.

This idea has been called Legofy It! (Do it with Lego!) And it is included as a button in the application they use in the faBrickator. The combination of 3D printing and Lego pieces to generate rapid prototypes is a breakthrough and surely we will soon be able to do it even at home. It will be a matter of letting the kids work and talk with the Lego.